Guide to Cement Valve Bag Making Machine: From Tuber to Bottomer

Among all the packaging solutions, valve paper bags stand out as the most efficient and environmentally friendly option for cement manufacturers. Behind every durable cement bag lies sophisticated machinery — the cement valve bag making machine.

This article offers a comprehensive guide to how these machines work, covering the process from tuber to bottomer, and explores why Tecon, a professional manufacturer of cement bag production lines, is trusted by cement plants around the world.

The Role of Cement Valve Bag Making Machines

Cement valve bags are a staple in the cement packaging industry because they combine durability, cost-efficiency, and ease of use. They are designed with a special valve opening that allows for quick filling and automatic sealing during the packaging process. To produce these bags at scale, cement manufacturers rely on cement valve bag making machines — advanced systems that automate every stage of production, ensuring consistent quality and productivity.

A complete cement bag production line typically includes two main types of machines:

● Tuber Machine

● Bottomer Machine

Each plays a critical role in transforming flat paper reels into finished, high-strength cement valve bags ready for filling.

Benefits of Using Valve Bags in Cement Packaging

Switching to valve paper bags offers multiple advantages for cement producers:

● Efficient filling process: The valve design allows quick and clean filling with automatic closure.

● Durability: Multi-ply paper ensures strong protection against moisture and damage.

● Sustainability: Paper valve bags are biodegradable and environmentally friendly.

● Branding potential: Custom printing enhances visibility and brand recognition in the market.

When combined with high-performance tuber and bottomer machines, these benefits are amplified through consistent production quality and reduced material waste.

The Cement Bag Production Line: Overview and Workflow

A modern cement bag production line integrates mechanical precision, intelligent control, and reliable automation. The process begins with the tuber machine, which forms the multi-ply paper tube, and ends with the bottomer machine, which converts these tubes into bags with closed and durable bottoms.

The workflow can be summarized in four main steps:

● Paper unwinding and alignment

● Tuber formation and cutting

● Bottom folding and gluing

● Valve creation and bag finishing

From Tuber to Bottomer: How Cement Bags Are Made?

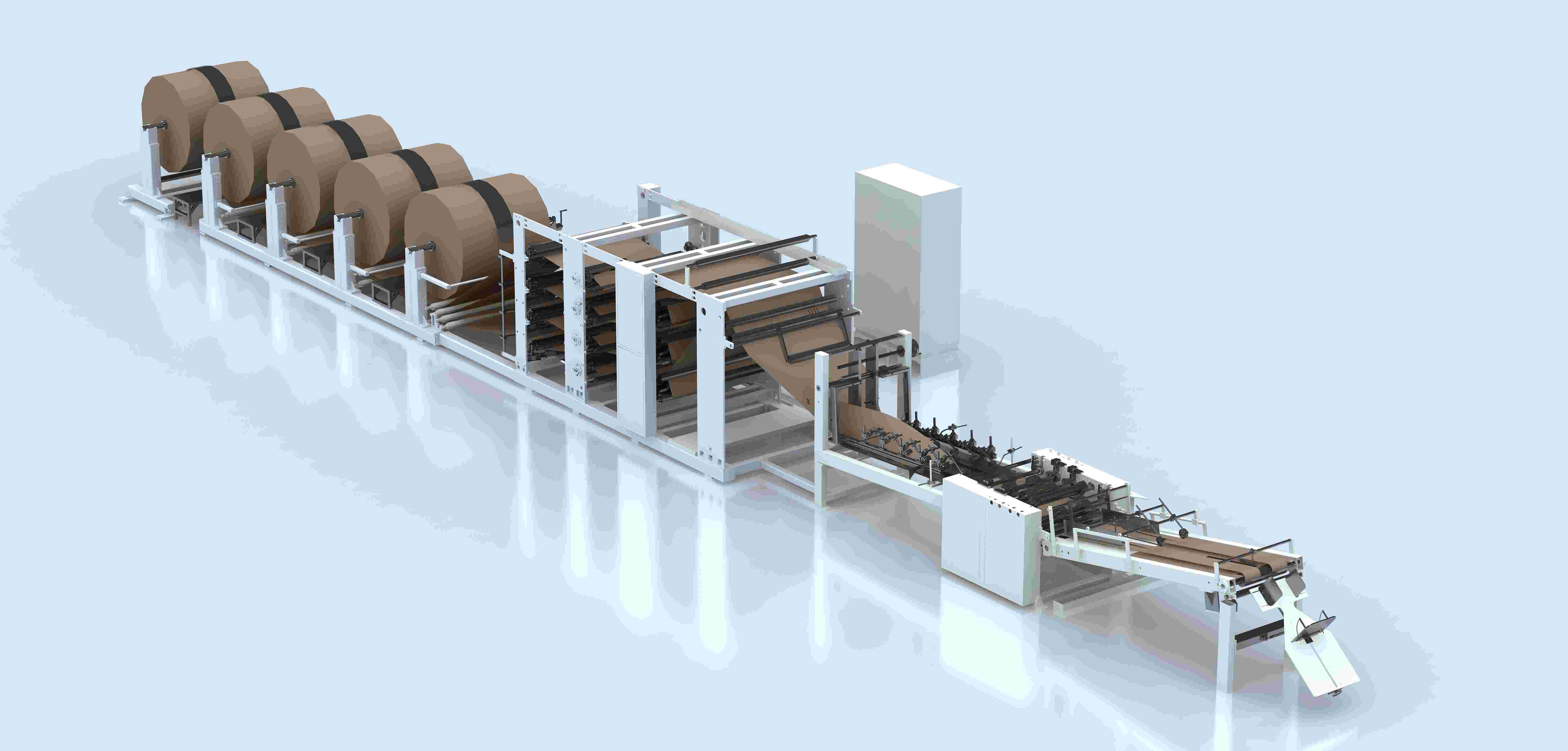

The Tuber Machine: Creating the Foundation

The tuber machine is the first step in the cement bag making process. Its job is to convert multiple layers of kraft paper into continuous paper tubes, which later become the bodies of the bags.

Main functions of the tuber machine:

● Paper feeding & tension control: Ensures each layer of paper unwinds smoothly and maintains uniform tension.

● Printing & patch pasting: Prints branding or product information and adds reinforcing patches around the valve area.

● Side gluing & tube forming: Precisely glues paper edges to form a seamless tube structure.

● Cutting: Cuts the continuous tube into individual sections of predetermined lengths.

A high-quality tuber machine can produce hundreds of paper tubes per minute with exceptional accuracy. This consistency is crucial for achieving strong, reliable bag bodies and minimizing waste in the next stage.

Tecon's tuber machines are widely recognized for their stable performance, user-friendly operation, and compatibility with a variety of paper grades. Each system can be customized to meet the specific requirements of different cement factories, including bag sizes, paper layers, and printing options.

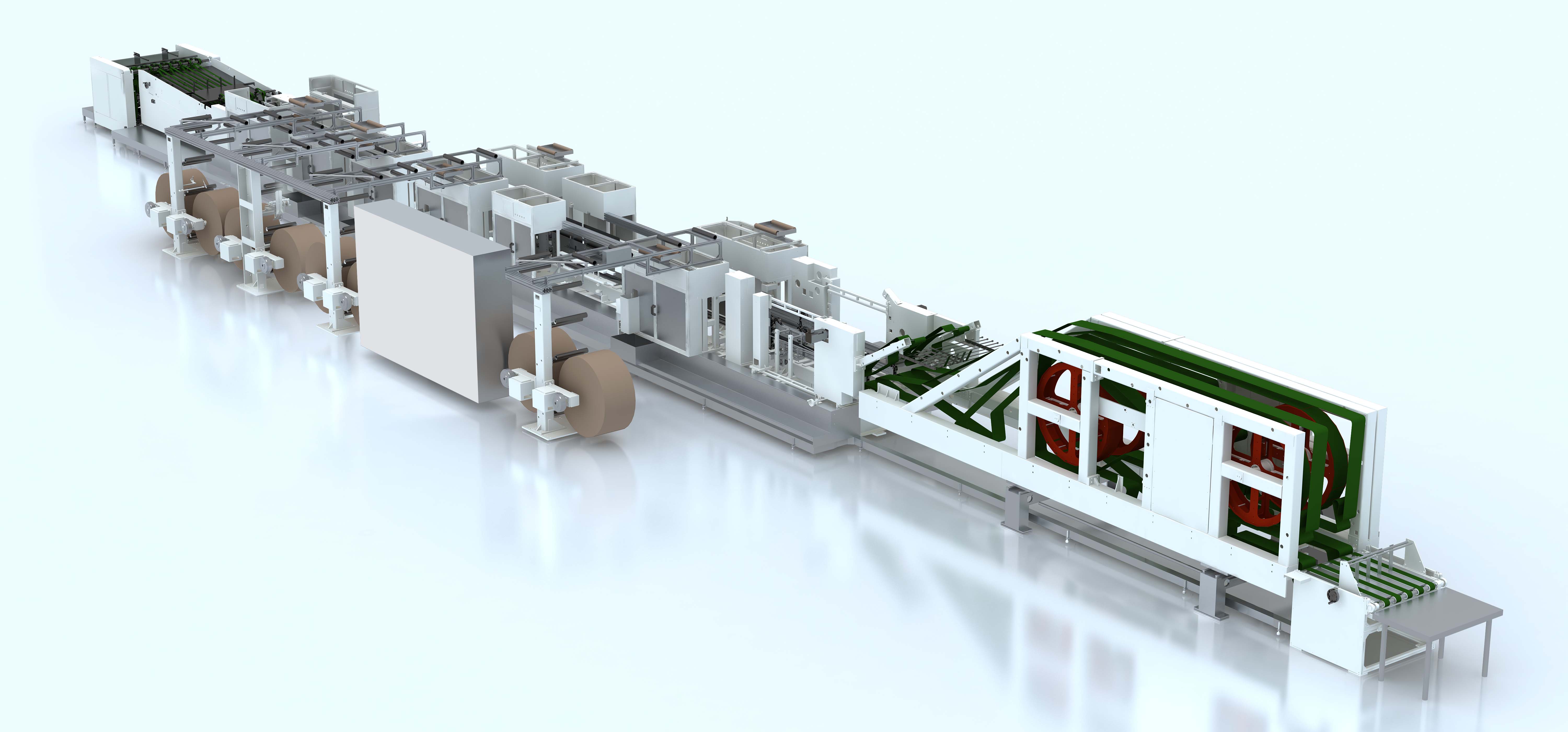

The Bottomer Machine: Completing the Bag

Once the paper tubes are formed, they are transferred to the bottomer machine — the second essential component of the production line. The bottomer machine transforms these tubes into finished valve bags by folding, gluing, and sealing the bottoms.

Main functions of the bottomer machine:

● Tube feeding and positioning: Accurately feeds each tube into the bottom forming section.

● Bottom opening and creasing: Prepares the tube ends for folding.

● Bottom folding: Creates precise triangular folds to form a square or rectangular base.

● Bottom gluing and sealing: Applies adhesive and presses the bottom firmly for a strong, leak-proof closure.

● Valve insertion: Attaches or forms the valve piece, which enables easy filling during cement packaging.

The bottomer machine ensures that each bag bottom is sealed tightly to prevent leakage during transportation or storage. The Tecon bottomer machine offers high automation, consistent gluing precision, and flexibility in bag formats, making it a reliable choice for modern cement plants.

High Speed Valve Bag Bottomer Machine

Key Considerations When Investing in a Cement Valve Bag Making Machine

Before investing in a cement valve bag making machine, cement plant managers should evaluate several factors to ensure long-term profitability:

● Production Capacity: Choose a system that aligns with your daily cement output.

● Automation Level: Advanced automation reduces labor costs and operational errors.

● Maintenance Requirements: Opt for machines with accessible parts and local technical support.

● Customization Options: Ensure the equipment can produce different bag sizes or designs as market demands evolve.

● Manufacturer Reputation: Work with an experienced supplier like Tecon, known for its reliability and service.

By taking these factors into account, cement factories can optimize both their production efficiency and product quality.

Conclusion

The production of cement valve bags is a complex process that combines mechanical precision, material science, and smart automation. From the tuber machine that forms the paper tubes to the bottomer machine that gives the bag its final shape, every step requires accuracy and consistency.

For cement manufacturers looking to optimize their packaging line, choosing a reliable partner is crucial. Tecon, a leading cement paper bag production line manufacturer, provides comprehensive solutions tailored to each client's needs. With advanced tuber and bottomer machines, customized configurations, and global technical support, Tecon helps cement plants achieve higher efficiency, better product quality, and long-term sustainability. Feel free to contact Tecon at info@newtecon.com for more detailed information.