How Much Does a Valve Cement Bag Making Machine Cost?

In the cement packaging industry, choosing the right valve cement bag making machine can significantly impact productivity, efficiency, and cost-effectiveness. Whether you are starting a new production line or upgrading an existing one, understanding the valve cement bag making machine price is crucial. This article explores the cost range, factors affecting pricing, and what to consider when buying a valve bag making machine to help you make an informed decision.

Understanding Valve Cement Bag Making Machines

A valve cement bag making machine is a specialized industrial machine used to manufacture paper or plastic bags with a valve opening. These bags are primarily used for packing powdered materials like cement, gypsum, flour, and chemicals. The valve design allows for automated filling and secure sealing, making them ideal for high-speed, high-volume packaging.

Valve bags can be made from a variety of materials, including multi-layer kraft paper, PP woven fabric, and BOPP film. A valve bag making machine is designed to handle these materials with precision, speed, and minimal waste.

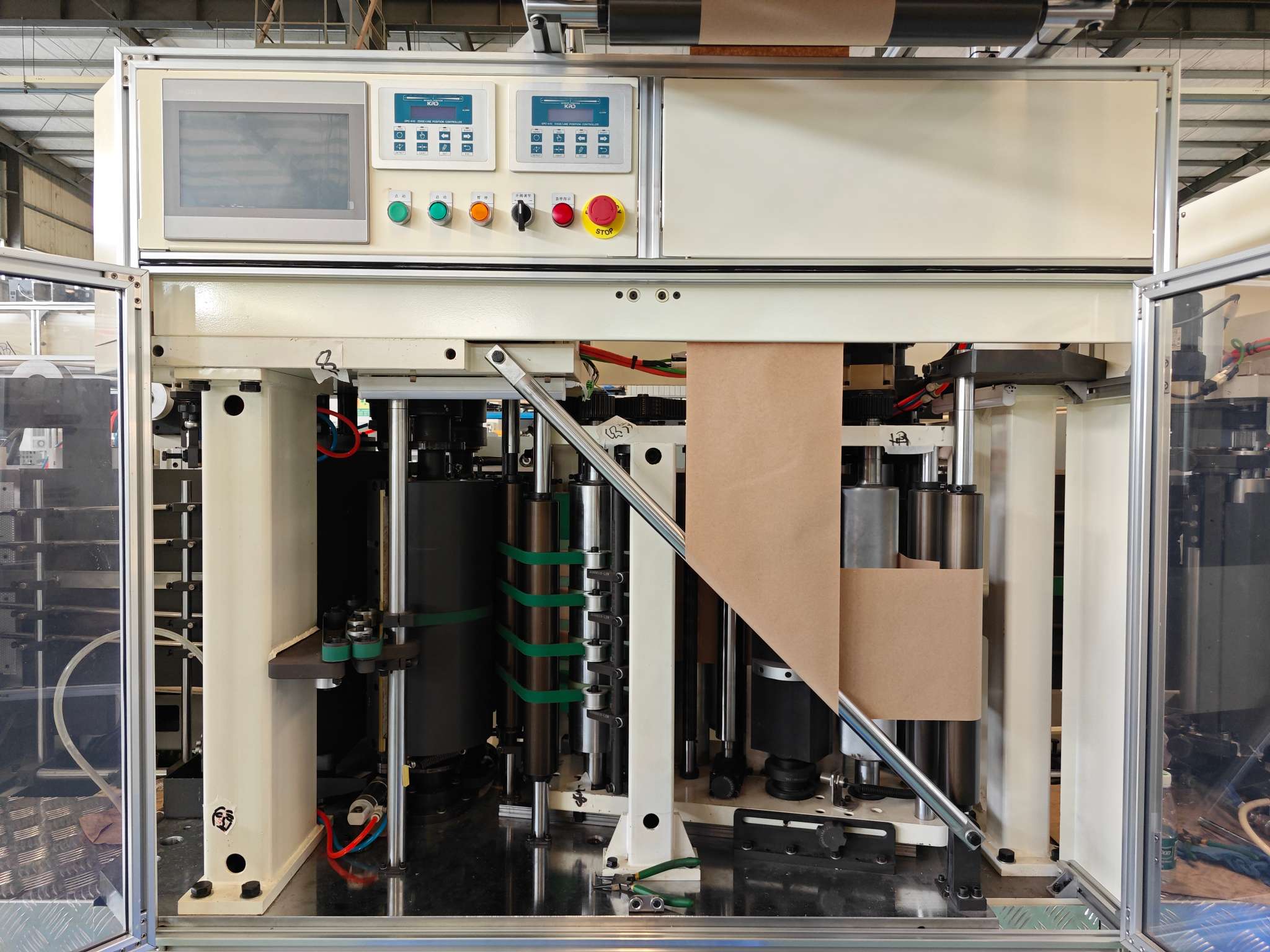

Global Cement Bag Making Machine Can Be Customized

Average Valve Cement Bag Making Machine Price

The valve cement bag making machine price varies widely depending on several factors, including:

● Automation level (semi-automatic vs. fully automatic)

● Production capacity (bags per hour)

● Material compatibility

● Machine brand and origin

● Additional features (such as inline printing, bottom pasting, valve insertion, etc.)

Here’s a general price range based on machine specifications:

| Machine Type | Price Range (USD) |

| Entry-Level Semi-Automatic | $25,000 – $40,000 |

| Mid-Range Fully Automatic | $50,000 – $100,000 |

| High-End Custom-Built Machines | $120,000 – $250,000+ |

Prices can vary based on the supplier and additional customization. For instance, machines sourced from China may offer competitive pricing, while European machines tend to be more expensive due to higher quality standards and advanced technology.

Key Factors Influencing the Price of Valve Bag Making Machine

1. Automation Level: Fully automatic valve bag making machines typically cost more than semi-automatic machines. However, they offer higher efficiency, less labor dependency, and long-term savings.

2. Production Speed and Capacity: Machines with a higher output (e.g., 120+ bags per minute) are more expensive but beneficial for large-scale operations. Small manufacturers might opt for lower-capacity machines to save on upfront costs.

3. Material and Bag Type Support: Some machines are specialized for kraft paper valve bags, while others can handle PP woven valve bags or laminated bags. A machine with multi-material compatibility is more versatile—and usually more expensive.

4. Customization and Integration: If your production line needs special features like inline flexographic printing, barcode labeling, or robotic stacking, expect the valve cement bag making machine price to increase.

5. Brand and After-Sales Support: Top-tier brands often come at a premium price due to their durability, reliability, and global service networks. Conversely, emerging brands may offer more competitive pricing but limited support.

Tips for Buying a Valve Bag Making Machine

Before investing, consider the following tips:

Evaluate your production volume – Choose a machine that matches your daily output requirements.

Material compatibility – Ensure the machine can handle the materials you plan to use.

Local regulations – Make sure the machine complies with local safety and environmental standards.

Supplier credibility – Work with reputable suppliers that offer warranties, training, and spare part availability.

Total cost of ownership – Include maintenance, operation, and labor costs in your evaluation, not just the purchase price.

FAQs About Valve Cement Bag Making Machines

1. What is a valve cement bag making machine?

A valve cement bag making machine is specialized equipment designed to produce valve-type bags used for packaging powdered materials like cement, plaster, or chemicals. These machines can create multi-wall paper, PP woven, or laminated valve bags efficiently and consistently.

2. How much does a valve cement bag making machine cost?

The valve cement bag making machine price ranges from $25,000 to over $250,000, depending on automation level, production speed, material compatibility, and included features. Fully automatic machines cost more but offer higher efficiency and output.

3. What factors affect the price of a valve bag making machine?

Several factors influence the valve bag making machine price, including:

● Machine automation (semi vs. fully automatic)

● Output capacity (bags per minute)

● Material versatility (paper, PP woven, BOPP, etc.)

● Integrated features (printing, bottom pasting, valve inserting)

● Brand reputation and after-sales support

4. What types of bags can be made with a valve cement bag machine?

These machines typically produce:

● Kraft paper valve bags

● Multi-wall valve bags

● PP woven valve bags

● Laminated cement bags

● BOPP valve bags

Customization options may allow for size and design flexibility.

5. Can one machine handle both paper and plastic valve bags?

Some high-end valve cement bag making machines are designed for multi-material compatibility, allowing them to handle kraft paper, PP woven, and laminated materials. However, not all machines offer this feature, so it’s important to confirm before purchase.

6. What is the typical production speed of a valve bag machine?

Production speeds vary by model. Semi-automatic machines can produce around 20–40 bags per minute, while fully automatic machines can reach up to 120+ bags per minute. Your production needs will determine the best fit.

7. Is operator training required for valve cement bag making machines?

Yes. Proper training ensures efficient machine use, reduces downtime, and extends machine lifespan. Many suppliers offer on-site or remote training as part of the purchase package.

8. What kind of maintenance do these machines require?

Regular maintenance includes:

● Lubrication of moving parts

● Cleaning dust and debris

● Replacing worn-out components

● Calibration of cutting and pasting units

Following the manufacturer’s maintenance schedule ensures consistent performance and durability.

9. Are spare parts readily available?

Most reputable manufacturers and suppliers offer spare parts and technical support. It’s important to choose a supplier with reliable after-sales service and a global parts distribution network.

10. Can the machine be customized for different bag sizes and specifications?

Yes, many valve bag making machines offer modular or customizable configurations to accommodate various bag sizes, shapes, valve positions, and printing needs. Be sure to discuss customization options with the supplier.

Valve Bag Making Machine Manufacturer

Conclusion

Understanding the valve cement bag making machine price is more than just knowing the numbers—it’s about recognizing the value behind the features, technology, and reliability. Whether you’re a small packaging startup or a large cement manufacturer, investing in the right valve bag making machine can enhance your operational efficiency and reduce long-term costs.

If you're comparing models or vendors, always request a detailed quote that includes installation, shipping, training, and after-sales service. The right machine is an investment in your company’s future growth and productivity. For those seeking a balance between performance, durability, and cost-effectiveness, Tecon valve cement bag making machines are worth considering. Browse the Tecon Website or contact us at info@newtecon.com for more information about custom valve cement bag making machines.