Top Valve Cement Bags Making Machines for Efficient Packaging in 2025

Packaging plays a crucial role in product preservation and transportation in the construction and building materials industry. Cement, a highly demanded material globally, requires robust and efficient packaging solutions. Valve cement bags are a preferred choice due to their superior sealing and ease of filling. As the demand for cement bags rises in 2025, choosing the right valve cement bags making machines becomes essential for manufacturers to ensure efficiency, reduce waste, and maintain high-quality packaging standards.

Why Valve Cement Bags?

Valve cement bags are designed with a unique valve mechanism that allows quick and dust-free filling of cement powder. Unlike traditional open-mouth bags, valve bags offer better sealing, minimizing moisture ingress and product spillage. This feature makes them highly popular in cement packaging, providing an eco-friendly and cost-effective solution.

Top Valve Cement Bags Making Machines in 2025

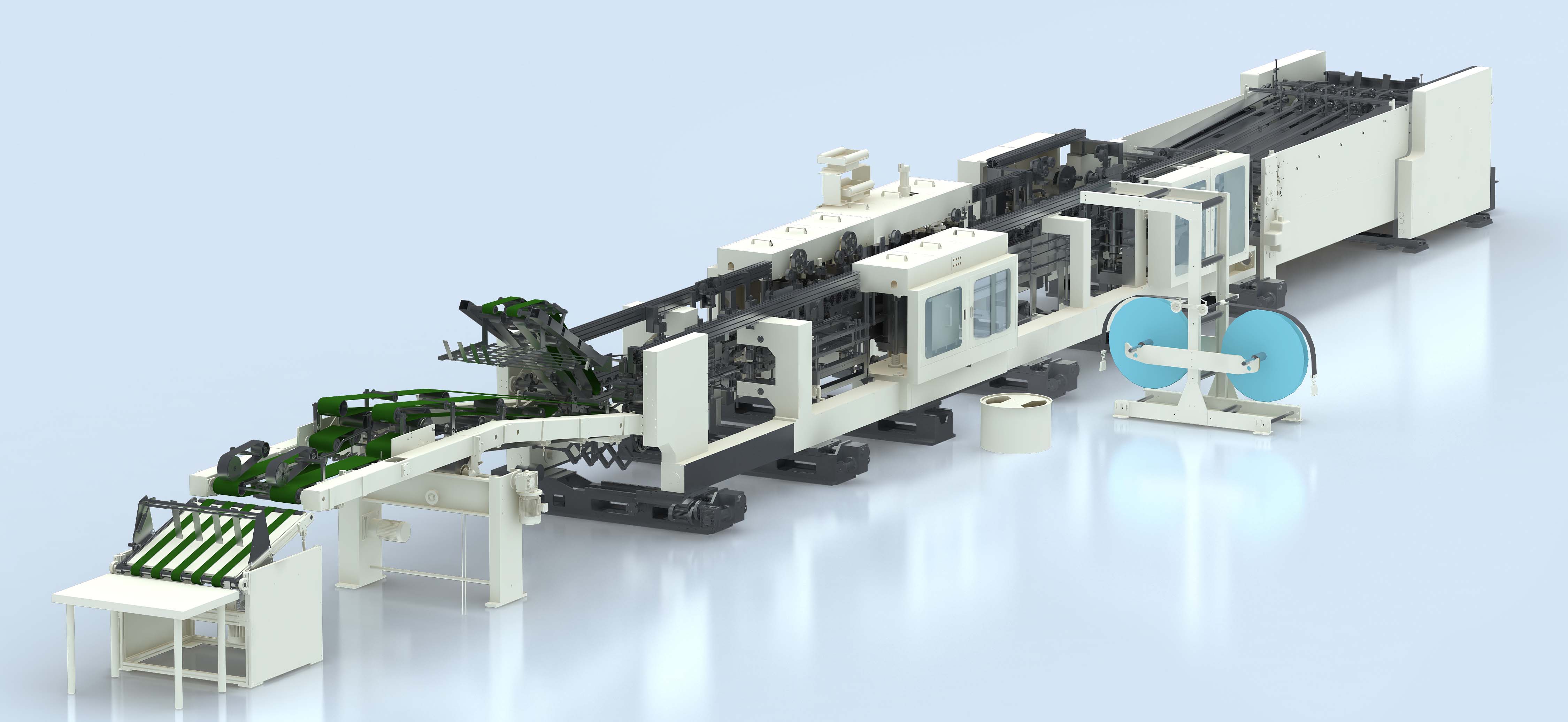

To produce high-quality valve cement bags, manufacturers often rely on a series of specialized machines. Tecon, a leading manufacturer of valve bag making machines, offers a comprehensive solution through three main machines in the valve bag production line:

The tuber machine creates the bag blank by forming the flat polypropylene (PP) or polyethylene (PE) woven fabric into a tube shape. This is the first step where the bag body is formed, known as tube making.

Bottomer Machine (Bottom Sealing)

After the tube is formed, the bottomer machine seals the bottom of the bag tube. This process, called bottom sealing, ensures the bag can securely hold the cement once filled.

Valve Making Machine (Valve Processing)

Finally, the valve-making machine processes the valve mouth, creating the self-closing valve that defines the valve cement bag. This final set completes the bag, turning it into a valve bag ready for filling.

The finished product, a valve cement bag, is widely used in industries like cement, chemicals, and construction materials for automated packaging lines, enhancing efficiency and product protection.

Tecon tuber and bottomer machines are integral to modern valve bag manufacturing processes. With their advanced automation features, high production speeds, and flexibility in handling various materials and designs, these machines provide manufacturers with the tools necessary to meet growing market demands efficiently. Investing in Tecon tuber and bottomer machines not only enhances production capabilities but also ensures high-quality output that meets industry standards.

Valve Cement Bags Making Machines

Features to Look for in Valve Cement Bags Making Machines

When selecting valve cement bags making machines, manufacturers should prioritize several key features:

High-speed production capability: Efficient machines can produce thousands of bags per hour, meeting large-scale packaging demands.

Precision sealing and valve formation: Ensures airtight bags that protect cement from moisture.

Durability and low maintenance: Machines built with high-quality materials reduce downtime.

Automation and user-friendly controls: Modern machines incorporate PLC systems for easy operation and consistent output.

Compatibility with various bag sizes and materials: Flexibility is vital for manufacturers catering to different packaging specifications.

Benefits of Using Advanced Valve Cement Bags Making Machines

Improved Packaging Efficiency: Automation reduces manual labor, increases production speed, and lowers error rates.

Enhanced Product Protection: Valve bags manufactured with precision machines reduce moisture penetration and cement contamination.

Cost Savings: High-speed machines cut down packaging time, minimizing labor costs and material waste.

Sustainability: Many modern machines support eco-friendly materials and optimize material usage to reduce environmental impact.

Customization Options: Printing and sizing flexibility help companies adapt to market trends and customer needs.

Trends in Valve Cement Bags Packaging for 2025

With increasing environmental concerns and stricter regulations, manufacturers are shifting towards sustainable packaging solutions. Valve cement bags made from recyclable materials, combined with energy-efficient bag making machines, represent the future of cement packaging. Integration of IoT and smart sensors in machines also enables real-time monitoring and predictive maintenance, enhancing overall productivity.

FAQ: Valve Cement Bags Making Machines for Efficient Packaging

Q1: What is a valve cement bag, and why is it preferred for cement packaging?

A: A valve cement bag features a self-closing valve that allows fast, dust-free filling. It provides better sealing against moisture and contamination compared to traditional open-mouth bags, making it ideal for cement packaging.

Q2: What are the main advantages of using valve cement bags making machines?

A: These machines offer high-speed production, precise valve formation, consistent sealing, reduced labor costs through automation, and compatibility with various bag sizes and materials.

Q3: How fast can modern valve cement bags making machines produce bags?

A: Advanced machines can produce anywhere from 80 to over 120 valve cement bags per minute, depending on the model and automation level.

Q4: Are valve cement bags making machines suitable for different bag sizes?

A: Yes, most modern machines support a range of bag sizes, typically from 20kg to 50kg, and allow easy size adjustments to meet different packaging requirements.

Q5: What features should I look for when buying a valve cement bags making machine?

A: Important features include production speed, valve sealing precision, automation level, ease of maintenance, durability, energy efficiency, and compatibility with printing and customization.

Q6: Can valve cement bags making machines handle eco-friendly or recyclable materials?

A: Yes, many newer machines are designed to work with sustainable materials and optimize material usage to support environmentally friendly packaging solutions.

Q7: Is automation necessary for efficient valve cement bag production?

A: While semi-automatic machines exist, fully automatic valve cement bags making machines significantly improve production efficiency, reduce errors, and lower labor costs.

Q8: What are the maintenance requirements for valve cement bags making machines?

A: Maintenance varies by machine model but generally includes regular cleaning, lubrication, valve alignment checks, and timely replacement of wear parts to ensure smooth operation.

Q9: How does the valve mechanism in the bags improve packaging efficiency?

A: The valve mechanism allows cement to be filled quickly without opening the entire bag mouth, reducing dust emissions and making the filling process faster and cleaner.

Q10: Are there any smart technologies integrated into valve cement bags making machines in 2025?

A: Yes, some machines now incorporate IoT-enabled sensors for real-time monitoring, predictive maintenance, and enhanced automation control, boosting overall productivity and reducing downtime.

Conclusion

Choosing the right valve cement bags making machines is vital for cement manufacturers aiming to boost packaging efficiency and product quality in 2025. Automatic, high-speed, and versatile machines from leading manufacturers offer tailored solutions for every scale of operation. By investing in cutting-edge valve bag machines, especially integrated production lines like Tecon’s tuber, bottomer, and valve making machines, companies can enhance their competitive edge while supporting sustainable packaging initiatives.