Tuber Machine and Bottomer Machine in Valve Bag Making

Valve bag making is a critical process in various industries, particularly for packaging materials like cement, chemicals, and food products. Central to this process are the tuber machine and bottomer machine, which work in tandem to produce high-quality valve bags.

Understanding the Valve Bag Making Process

Valve bags are designed with a valve opening that facilitates easy filling and dispensing of contents while minimizing leakage. The production of these bags involves several steps, primarily executed by specialized machinery, including the tuber machine and bottomer machine.

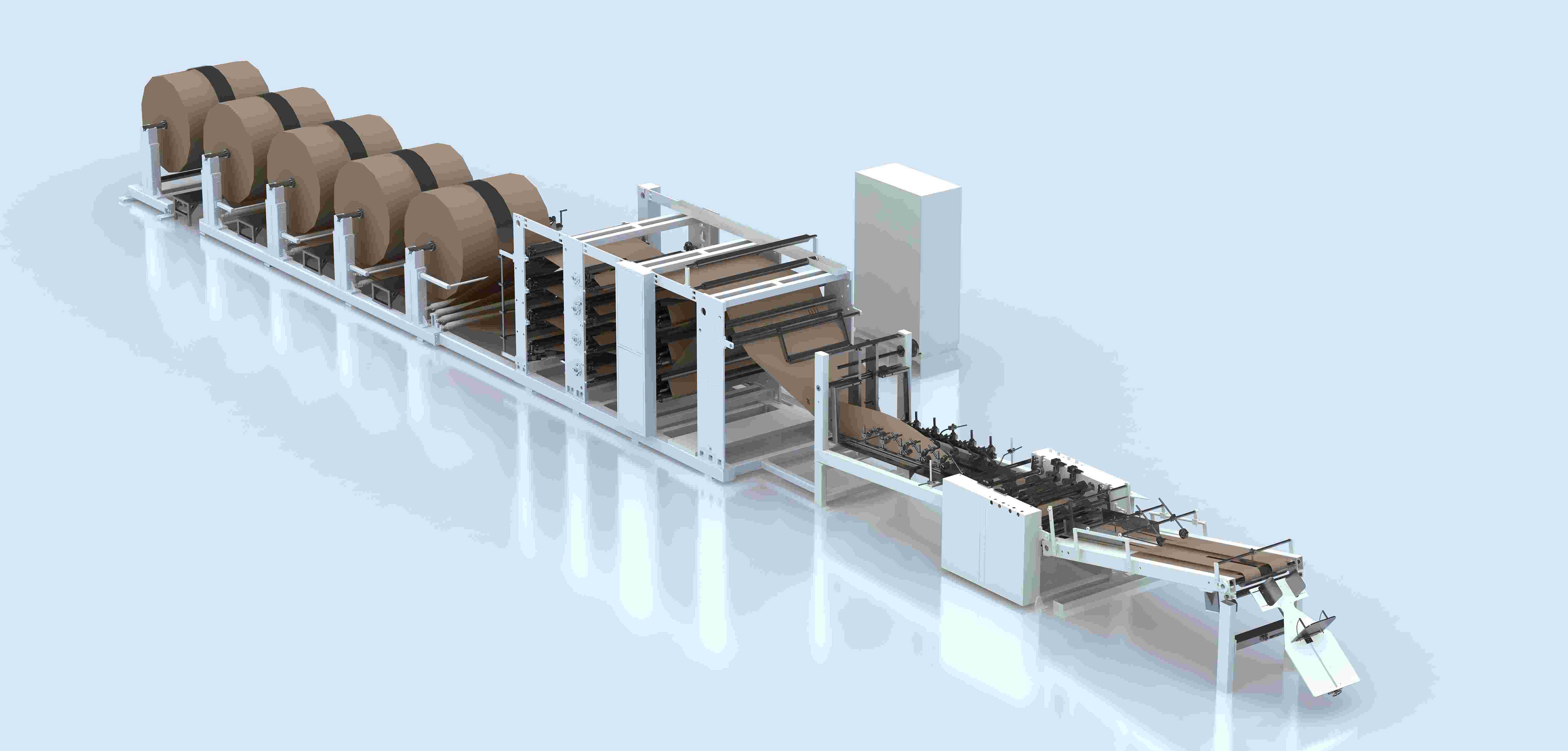

Tuber Machine

The tuber machine is responsible for creating the initial structure of the valve bag. It forms paper tubes from flat sheets of material, which serve as the basic framework for the bags. Key functions of the tuber machine include:

● Tube Formation: The machine shapes raw material into cylindrical tubes.

● Sewing Capability: It can sew or seal the edges of the tubes to ensure durability.

● High Production Speed: Most of the modern tuber machines can operate at speeds of up to 120 bags per minute, enhancing efficiency in production lines.

The tuber machine's design often incorporates advanced technology that allows for quick adjustments to accommodate different bag sizes and materials. This flexibility is crucial for manufacturers who need to respond rapidly to market demands.

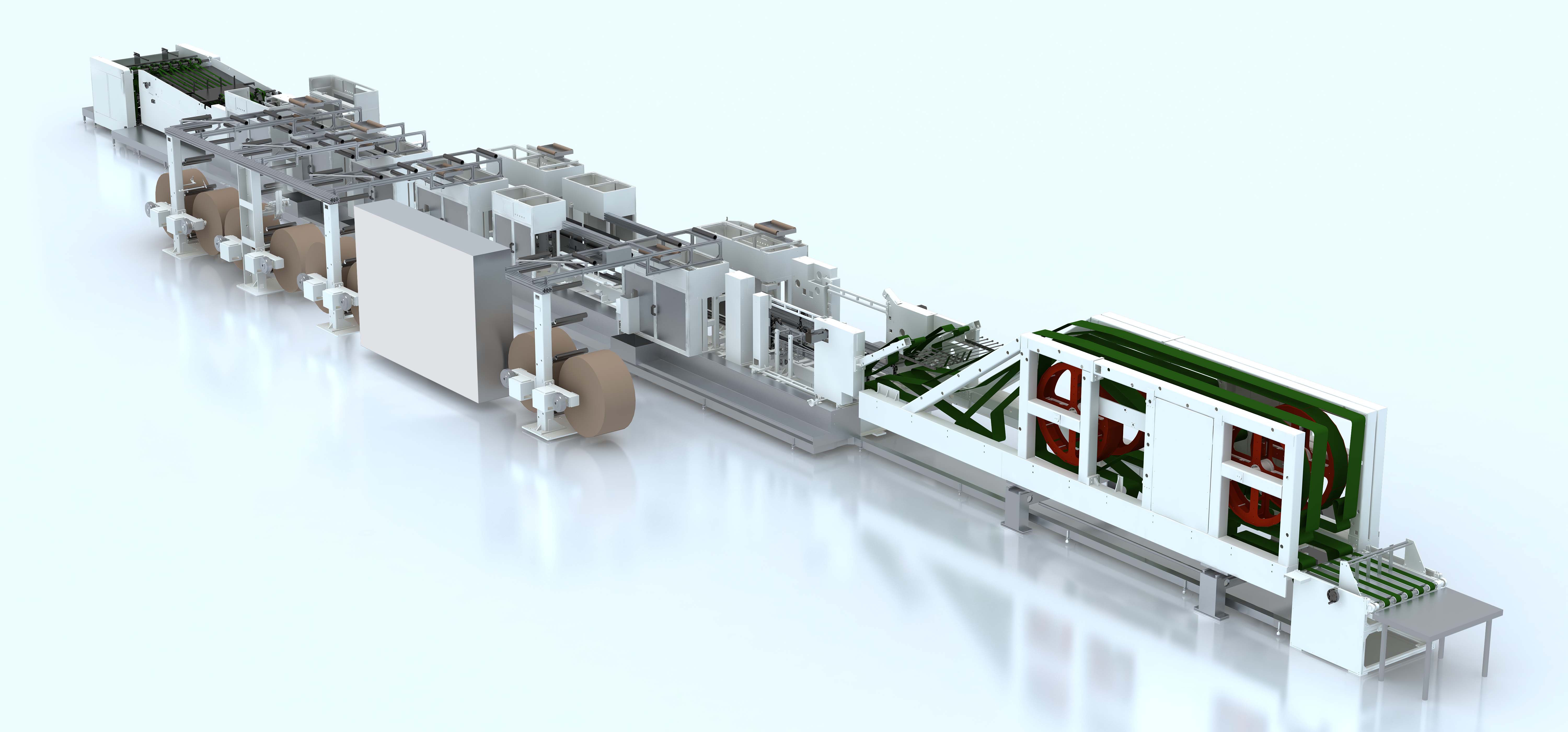

Bottomer Machine

Once the tubes are formed, they must be converted into complete valve bags. This is where the bottomer machine comes into play. Its primary functions include:

● Bottom Opening: The bottomer machine opens both ends of each tube.

● Folding and Gluing: It folds and glues the ends to create a secure closure.

● Compacting and Shaping: The machine compacts the bottom of the tube to form a stable base for the valve bag.

The integration of a bottom pasting mechanism ensures that each bag is not only functional but also meets industry standards for strength and durability. The bottomer machine can also be equipped with features that allow for customization, such as adding handles or printing directly onto the bags.

Industry Applications

The combination of tuber machines and bottomer machines is widely utilized across various sectors:

Construction Materials: Valve bags are commonly used for packaging cement, sand, and other construction materials due to their strength and ease of handling.

Agriculture: In agriculture, these bags are perfect for containing fertilizers, seeds, and animal feed.

Food Industry: Valve bags made from food-grade materials are used for packaging grains, flour, sugar, and other bulk food products.

Relationship Between Tuber, Bottomer, and Valve Bag Making Machine

Tuber Machine

The tuber machine is the first stage in the valve bag production line. Its primary function is to convert flat sheets of paper or plastic into cylindrical tubes. The efficiency and speed of the tuber machine significantly impact the overall productivity of the valve bag making process.

Bottomer Machine

Once the tubes are formed by the tuber machine, they need to be completed into functional valve bags. This is where the bottomer machine comes into play. The bottomer machine is essential for transforming the initial tube produced by the tuber into a finished product that meets industry standards for strength and usability.

Valve Bag Making Machine

The term valve bag making machine often refers to a complete production line that integrates both tuber and bottomer machines along with additional equipment necessary for producing valve bags efficiently. This comprehensive system typically includes:

Tuber Machines: For creating the initial tube structure.

Bottomer Machines: For completing and sealing the bags.

Palletizers and Other Equipment: To automate packaging and handling processes after bag production.

By combining these machines into a single production line, manufacturers can streamline operations, reduce labor costs, and improve overall efficiency. This integration allows for continuous production with minimal downtime, ensuring that manufacturers can meet high demand without sacrificing quality.

In a word, the relationship between the tuber machine, bottomer machine, and valve bag making machine is foundational to effective valve bag production. The tuber machine initiates the process by creating tubes from raw materials, while the bottomer machine finalizes these tubes into complete valve bags ready for filling. Together, they form an essential part of a valve bag making system that enhances productivity and quality in packaging operations across various industries.

|

Machine |

Function |

Role in Production |

|

Tuber Machine |

Forms paper or plastic sheets into cylindrical tubes |

Initial stage of creating the bag structure |

|

Bottomer Machine |

Completes the tube into a finished valve bag by sealing the bottom |

Finalizes the bag by creating a secure bottom |

|

Valve Bag Making Machine |

Integrates tuber and bottomer machines for complete valve bag production |

Comprehensive system for efficient valve bag manufacturing |

This table succinctly captures the distinct functions and roles each machine plays in the valve bag production process.

Future Trends in Valve Bag Manufacturing

As industries evolve, so do manufacturing processes. Here are some trends influencing the future of valve bag making:

Sustainability Initiatives: With increasing environmental concerns, manufacturers are looking at biodegradable materials for valve bags. Tuber and bottomer machines will need to adapt to handle these new materials effectively.

Smart Technology Integration: The incorporation of IoT (Internet of Things) technology is becoming more prevalent in manufacturing processes. Smart tuber and bottomer machines can provide real-time data analytics on production efficiency and maintenance needs.

Customization Options: As consumer preferences shift toward personalized products, there is a growing demand for customizable valve bags. Manufacturers may need to invest in flexible machinery that can produce small batches with varying designs quickly.

Conclusion

The tuber machine and bottomer machine are integral components in the valve bag making process, each playing a vital role in producing high-quality valve bags for various industries. The tuber machine initiates the production by forming cylindrical tubes from raw materials, while the bottomer machine completes these tubes into functional bags with secure closures. Together, they form a comprehensive valve bag making machine system that enhances efficiency, quality, and adaptability in manufacturing. Tecon is a valve bag making machine manufacturer, contact us today to learn more about how our advanced machines can transform your business.