Valve Sack Production: Optimizing Output with Advanced Machinery

Valve sacks are critical components in industries such as construction, agriculture, and food packaging. Their ability to securely store and transport powdered or granular materials has made them indispensable.

Valve sacks are designed with built-in valves for easy filling and sealing, making them essential for bulk packaging applications. Industries such as construction use them for cement and mortar, agriculture for fertilizers and grains, and food packaging for flour and sugar.

In an era where efficiency, quality, and sustainability drive manufacturing processes, optimizing valve sack production is crucial. Relying on outdated methods can lead to inconsistencies, waste, and higher costs, making the adoption of advanced machinery a game-changer for manufacturers.

Challenges in Traditional Valve Sack Production

Traditional valve sack production methods come with several inefficiencies:

Inconsistent Quality: Manual processes often result in uneven cuts, weak seals, or poorly attached valves, leading to product defects.

High Material Waste: Outdated equipment lacks the precision needed to optimize material usage, increasing waste and costs.

Limited Speed and Scalability: Traditional methods struggle to meet high production demands, limiting a manufacturer’s ability to scale operations.

Energy Inefficiency: Older machines consume more power, contributing to higher operational costs and a larger carbon footprint.

The Role of Advanced Machinery in Valve Sack Production

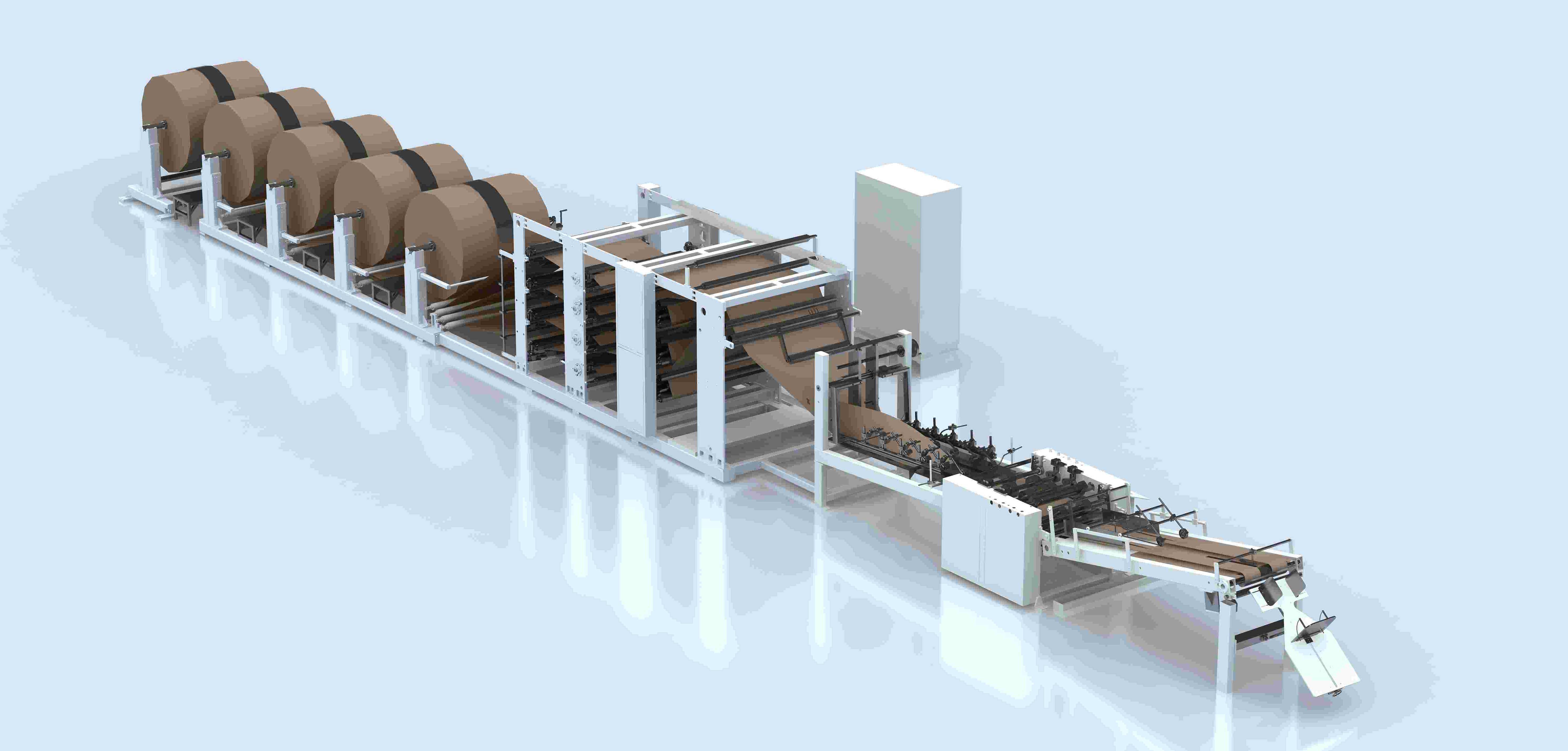

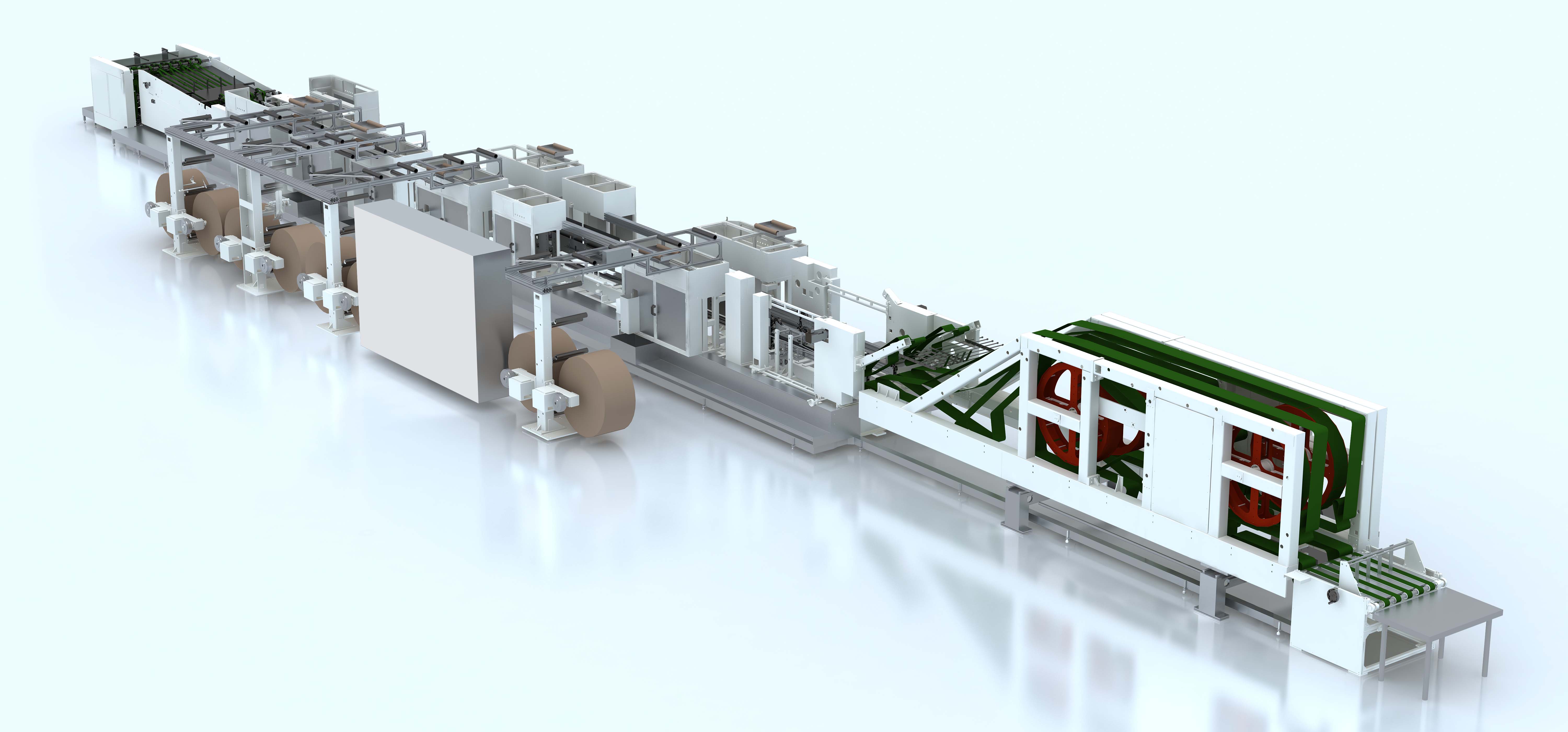

Advanced machinery addresses the inefficiencies of traditional production methods through automation and precision engineering. Below are the key types of equipment driving this transformation:

Valve Sack Making Machines: These machines automate the entire production process, including cutting, folding, pasting, and valve attachment. They ensure precise dimensions, strong seals, and consistent quality for every sack.

Advanced Printing Systems: Integrated printing systems allow manufacturers to customize sacks with logos, product details, and branding while maintaining high-quality finishes.

Valve Placement Units: Specialized units ensure the accurate placement and secure attachment of valves, reducing the risk of spillage or contamination during use.

Material Optimization Tools: Modern equipment optimizes the cutting and layering of materials, ensuring durability while minimizing waste.

By integrating these advanced tools, manufacturers can streamline their processes and significantly improve output quality.

Benefits of Upgrading to Advanced Machinery

Investing in modern machinery offers multiple advantages:

Higher Production Efficiency: Automated systems operate faster than manual methods, reducing production time and minimizing downtime caused by errors or maintenance issues.

Enhanced Product Quality: Precision cutting, folding, and sealing result in sacks that meet industry standards for durability and performance.

Reduced Material Waste: Advanced machines optimize material usage, leading to cost savings and reduced environmental impact.

Improved Sustainability: Energy-efficient machines help lower operational costs and support eco-friendly manufacturing practices, aligning with modern sustainability goals.

Customization Capabilities: With advanced printing and valve placement systems, manufacturers can meet specific client requirements, whether it’s branding or sack size.

Applications of Advanced Machinery in Valve Sack Production

Manufacturers worldwide have successfully leveraged advanced machinery to enhance their operations. For example:

Construction Materials: Cement manufacturers now produce durable sacks capable of withstanding harsh conditions.

Food Industry: Flour and sugar producers benefit from hygienic and precise sack production, ensuring compliance with food safety standards.

Agriculture: Farmers receive reliable sacks that prevent leakage and allow for easy handling.

Conclusion

Advanced machinery is changing valve sack production by addressing the inefficiencies of traditional methods. From increasing production speed to reducing waste and enhancing product quality, modern equipment offers manufacturers the tools needed to thrive in a competitive market.

For businesses looking to optimize their operations, adopting advanced machinery is not just an option—it’s a necessity. Explore the latest innovations in valve sack production to elevate your manufacturing capabilities and stay ahead of industry demands.